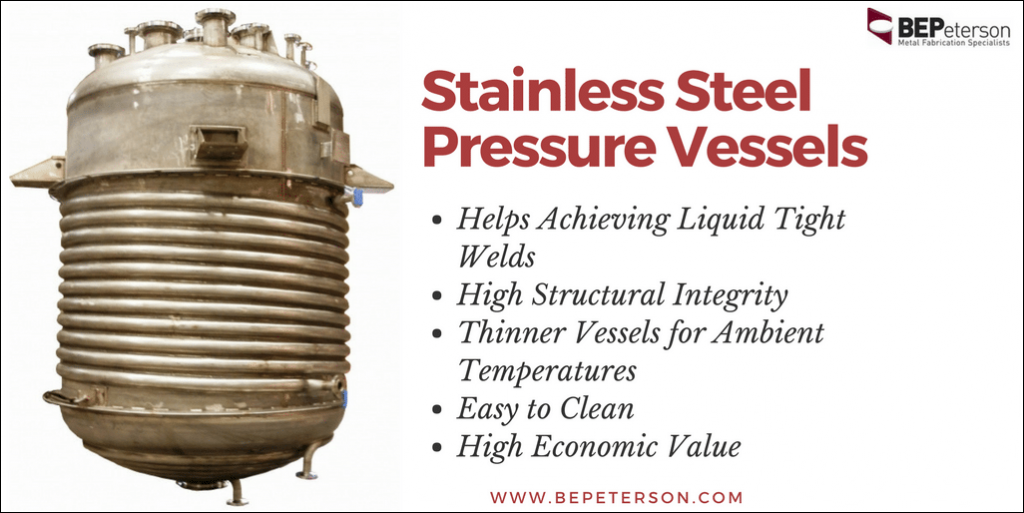

Pressure vessels are designed to contain liquids or gases at high pressure values. Typically pressure vessels are built using materials like stainless steel, aluminum, nickel alloys, carbon and low alloy steels, and duplex stainless steels. Over, the years, stainless steel pressure vessels have gained popularity due to several advantages offered by them. BEPeterson is one of the leading manufacturers of stainless steel pressure vessels in the US. All pressure vessels are designed per ASME standards, which helps us ensure all the client specified requirements are fulfilled. Examples of specific requirements include internal pressures, corrosion allowance, wind and seismic loading, operating temperature, volume, etc. In this post, we will discuss why stainless steel pressure vessels can be an asset to your process.

5 Reasons Why Should You Opt for Stainless Steel Pressure Vessels

The following reasons will help you understand why pressure vessels made from stainless steel are gaining popularity.

1. Helps Achieving Liquid Tight Welds: Stainless steel is a sturdy material, but can be easily fabricated to desired shapes. It allows machining to close tolerances. Pressure vessel leakages are very dangerous due to their storage contents. Experienced fabricators like us always take precaution to avoid leakage by hydro testing every vessel. Additional testing can include PT and RT. Also, the welding of stainless steel can be easily simplified by adding a single chemistry filler throughout the vessel.

2. High Structural Integrity: One of the key benefits of using stainless steel in pressure vessels is high structural integrity. The structural integrity is contributed by two factors – high strength and high durability. In addition to that, stainless steel pressure vessels require no additional protective coatings due to their high corrosion resistance. This helps reduce maintenance needs, and improve their service lives.

3. Thinner Vessels for Ambient Temperatures: Stainless steel has higher tensile strength than carbon steel and other metals, which enables producing thinner vessels at ambient temperatures.

4. Easy to Clean: Stainless steel pressure vessels are easy to clean.

5. High Economic Value: Proper maintenance and handling make these stainless steel pressure vessels a cost efficient choice. As known, corrosion is one of the major known causes of disintegration of vessels or equipment in the process industry. However, stainless steel is composed of iron and minimum 10.5% chromium, which helps prevent corrosion. The presence of chromium also contributes to the self- healing property of the steel. Another major fact is that stainless steel doesn’t react with gases or liquids that are stored inside the vessel. This helps reduce chances of accidents brought by a disastrous combination of metal and toxic gas or liquid.

All the above-mentioned reasons enable users to realize long term value of their investment. Also stainless steel is recyclable, which means users can easily reduce their carbon footprint. At BEPeterson, we provide various stainless steel designs including baffled jackets, half pipe, and internal pipe coil, tubesheets, etc. Our fabrication process allows us to produce high quality products. All our products are backed with our quality assurance guarantee.

VP of Business Development Dan Szczurko joins the podcast to discuss the pressure vessel business & market segmentation. Furthermore, he gives an overview of the sales process from a customer’s perspective.