Naval warships are under consistent threat of hypersonic missiles, rail guns, lasers, torpedoes, UAVs, ballistic missiles, active ship missiles, and more. To overcome this, the naval forces have been regularly investing in technology-driven self-defense strategies. They often partner with trusted companies to put these strategies into action. Acknowledging the need for security-centric technologies in the navy, Northrop Grumman offers solutions to address and resolve the problems faced by the navy. However, in order to design, develop, and produce advanced and effective naval systems, they collaborate with well-recognized manufacturers like BEPeterson. Being a highly-recognized manufacturer of ASME pressure vessels and reservoirs, the company has had several opportunities of working with Northrop Grumman. This post focuses on BEPeterson’s Northrop Grumman Reservoir development capabilities and tries to analyze what makes BEPeterson a proud manufacturer of Northrop Grumman reservoir vessels.

Northrop Grumman is a leading aerospace and defense technology company that helps its clients to overcome security threats and other unresolved challenges through its techno-centric solutions. The company combines the best practices of science, technology, and engineering to develop its solutions and is today considered one of the largest defense contractors in the world. The company is globally recognized for resolving the toughest problems related to defense sectors. Starting from World War II, the company has a proven history of offering techno-centric solutions to the army, air force, and navy.

Let us discuss the contribution of Northrop Grumman in the resolution of problems faced by the navy.

Contribution of Northrop Grumman in Naval Systems

Northrop Grumman has developed the following technological solutions for the navy.

- Anti-ship missile defense: This is a Doppler radar for the early detection of projected sea-skimming missiles.

- Electronic Warfare: This system offers advanced technological capabilities to naval warfighters.

- Full-spectrum Cyber: It is an integrated cyber technology that offers defensive and offensive abilities to naval warfighters.

- Integrated Bridge-System: It is a bridge system for large naval vessels integrated with defense equipment.

- Mine-hunting System: This is a field electro-optic system for mine identification.

- Multifunctional Workstations: These are naval workstations that support all nautical functions and ship system operations.

Along with the listed solutions for the navy, Northrop Grumman has developed the SEWIP Block 3 system. SEWIP stands for Surface Electronic Warfare Improvement Program. This system is third in the series of AN/SLQ-32 electronic warfare (EW) systems with advanced electronic attack (EA) capabilities to overcome the missile threats. Northrop Grumman has been at the forefront of this AN/SLQ-32 system for more than four decades. Reservoir vessels are integral to SEWIP Block 3 and other naval systems. BEPeterson is a trusted manufacturer of these reservoirs. Now let us discuss BEPeterson’s contributions to Manufacturing Northrop Grumman Reservoir Vessels.

A Brief Overview of Northrop Grumman Features of Northrop Grumman Reservoir Vessels Manufactured by BEPeterson

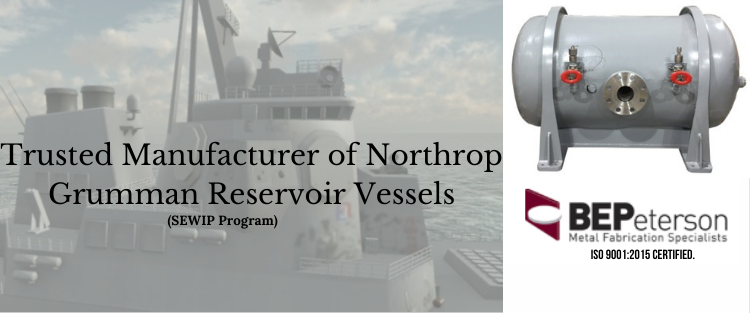

BEPeterson manufactures the reservoir vessels for SEWIP Block 3 system from Northrop Grumman. The system requires special quality reservoir vessels since naval systems are subjected to conditions like high pressure, corrosion, chemical exposure, tactical and anthropogenic environmental changes, etc. Due to these factors, the manufacturing of Northrop Grumman reservoir vessels is a complex and strenuous task. BEPeterson manufactures ASME-certified reservoir vessels for SEWIP Block 3 system.

The following are some specifications of Northrop Grumman reservoir vessels by BEPeterson.

- The reservoir vessels are compliant to ASME guidelines, and they can stand up to international quality standards.

- They are made of stainless steel in order to sustain high pressure in marine applications.

- They can sustain up to 10000psi pressure.

- BEPeterson is ISO 9001:2015 certified, and the reservoir vessels are compliant to ISO 9001 quality management standards (QMS).

- They are fabricated under ASME BPVC Section VIII and Section IX welding standards.

- The reservoir vessels are tested under Inspection and Test Plan (ITP) protocols.

Extensive ASME manufacturing capabilities, in-depth understanding of client requirements, and unmatched technical expertise make BEPeterson a proud manufacturer of Northrop Grumman Reservoir Vessels.