- ASME/PED/CRN

- ISO 9001:2015 NSAI Certified

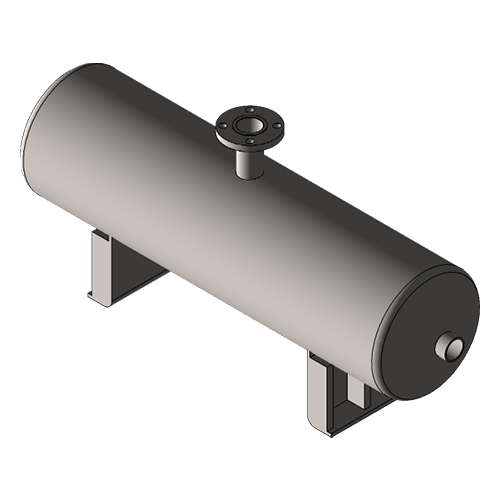

PRESSURE VESSEL DESIGN

Pressure Vessel Design

Pressure vessels are closed containers designed to hold either gases or liquids at pressures higher or lower than ambient air pressure, known as the Design Pressure, and at a specific temperature, known as the Design TemperaturePoorly designed vessels result in significant safety hazards. The design and certification of pressure vessels is governed by design codes like the ASME Boiler and Pressure Vessel Code in north America, the Pressure Equipment Directive in the European Union (PED / CE), and the BSA B51 code in Canada (CRN). BEPeterson is a holder of the ASME single certification mark and a certificate of authorization. We design and fabricate vessels in accordance with the requirements of the ASME Boiler and Pressure Vessel Code.

Pressure Vessels Designed to Code

We design pressure vessels to Section VIII standards. This means the design, fabrication, inspection and certification of pressure vessels that operate at internal or external pressures exceeding 15 psig.

Our engineering and design services are done in accordance with ISO 9001:2015 and ASME requirements. Our system of engineering reviews and customer approvals means that both client and code requirements are met.

Designing a Customer’s Vessel

BEPeterson can design your pressure vessel based with a minimum amount of input data. You can use the Vessel Quotation Checklist to complete as much information you have available. Send the Vessel Quotation Checklist to BEPeterson and we will do the rest. BEPeterson will design your pressure vessel to the latest ASME code to ensure the highest manufacturing standards for performance and safety.

International Standard Compliance

Cutting-edge Welding Processes

Rigorous Testing & Inspection

Detailed Reports

International Standard Compliance

- All vessels meet all applicable codes and standards (ASME, PED, and CRN).

- As a trusted ammonia tank manufacturer, BEPeterson delivers products with on time delivery, and to certified ISO 9001 quality standards.

Cutting-edge Welding Processes

- BEPeterson uses modern welding equipment, including submerged arc, which provides efficient and smooth welding of ammonia tanks.

- We meet the most sophisticated weld procedures using TIG, MIG, SAW, SMAW, FCAW with a variety of wire and fluxes.

- Qualified ASME Welders and an extensive radiographic capability support all types of ASME Section VIII code construction.

- Our welding capability is supported by a weld-engineering group consisting of multiple CWIs, and in-process weld inspectors.

Rigorous Testing & Inspection

- Every shell and tube heat exchanger is fully documented and inspected by authorized ASME Inspectors.

Detailed Reports

- BEPeterson provides full documentation, material test certificates, RT, and hydro test reports prior to shipment.

Our Design Software

We use COMPRESS® software, the engineering productivity tool that models, calculates and creates reports for ASME pressure vessel design.

We create our fabrication drawings in SolidWorks® 3D Tools, AutoCAD® and AutoCAD Inventor®.

Engineering Capabilities:

- Pressure vessel design – ASME and non-code

- Tank design

- ASME vacuum furnace design

- Solidworks

- 3D modeling

- DWG

- ASCI

- DXF

- IGES

When you partner with BEPeterson for all your pressure vessel needs, you partner with the best.

Technical Specifications

- Chemical & Agricultural

- Energy / Oil , Gas, Alternative

- Military / Defense

- Resins, Polymers, Coatings & Adhesives

- Water & Chemical Filtration

- Process Industries

- Environmental

- Plastics & Rubber

- Hydro-test

- Radiography

- He Leak Testing

- PMI (Positive Material Identification)

- NDE – PT, MT, UT

- Dimensional – Fero Arm

- Ferrite Testing

- Impact Testing

- ASME Section 8 Div 1

- U,R,S & UM stamps

- TUV

- ISO 9001:2015 certified

- CE, PED and CRN upon request

- ASME Section 8 Div 1

- U,R,S & UM stamps

- TUV

- ISO 9001:2015 certifiedå√

- CE, PED and CRN upon request

- Vessel Thickness :

- Up to 3″ Thickness

- Vessel Length :

- Up to 100′ OAL

- Vessel Pressure Range :

- Full Vacuum to 6000 PSI

- Vessel Diameter :

- Up to 13′ Diameter

- Overall Vessel Weight :

- Up to 40,000 LBS.

- Jacketed Vessels :

- Dimpled, Half-pipe, Std.