- ASME/PED/CRN

- ISO 9001:2015 NSAI Certified

POWER GENERATION

Helping to power the world! BEPPeterson has a rich legacy in manufacturing metal parts for the power and utilities industry. Our products are integral to power plants and utilities worldwide, from scrubbers and coal Low NOx burners to large ductwork, boiler assemblies and other parts and components.

Robust, reliable metal components engineered to exact requirements boost operation and increase productivity for the power industry. BEPeterson provides custom fabrication of metal parts for power generation, keeping utilities and power plants running smoothly. We design, engineer and manufacture quality metal parts and are your complete technical solution provider.

Our Products

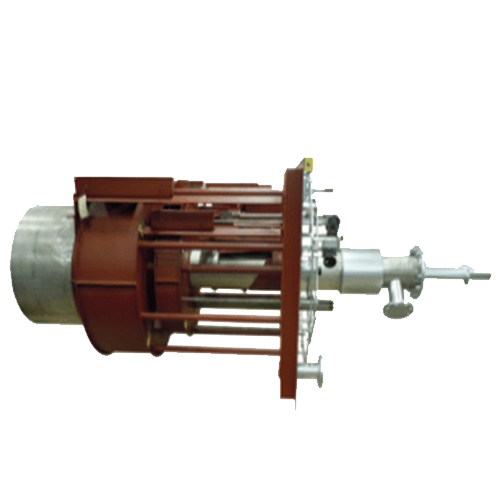

We have an extensive portfolio of durable solutions and provide essential functionality to the energy industry globally. BEPeterson designs and produces Low NOx coal burners, coal burner nozzle tips, boiler windboxes and SOFA windboxes for coal and gas wall fired burners.

BEPeterson power generation parts feature the following:

- Our parts can be tailored to your unique business and project needs.

- We produce metal components for power generation for new and retrofit applications.

- Using carbon steel and high-temperature stainless steel, we provide durable solutions with overlay protection for our coal nozzle burner tips.

With innovation and a commitment to quality, our capabilities include a comprehensive list of products and services, from overfire air systems to dampers.

More of our products include:

- Ash control valves

- Boiler components

- Low NOx burners

- Burner tips

- Ceramic/Refractory lined products

- Coal compartment assemblies

- BEPeterson provides custom Hardfacing where abrasion resistance is critical

- Cyclones

- Ductwork

- Low NOx wind boxes

- Sofa registers

- Vortex finders

Our Process

We streamline the entire process from start to finish to save you time. Our supportive team works with you to devise a solution that best suits your industry and application, ensuring superior results.

1. The Design Phase

BEPeterson offers design support so you’re assured of precise outcomes. The design stage includes:

- Design support: We work with you to verify the existing design or work on a new one.

- Practical solutions: We build our systems according to safety, functionality and cost-effectiveness.

- Industry compliance: All our fabricated metal components adhere to the American Society of Mechanical Engineers (ASME) industry codes.

- Wide selection: Since we customize metal parts for various industries, you’ll have access to a range of options.

2. The Engineering Stage

You get high-quality service with state-of-the-art technology and world-class support through:

- A dedicated engineer: We assign a specific engineer to every project to ensure we meet and exceed your project needs.

- Advanced software: We use Solidworks Simulation (FEA), Solidworks, AutoCAD, and Codeware Compress to design and engineer your fabricated metal components.

- Quality control: Before material procurement and manufacturing start, we review all products for compliance and manufacturability.

Request a Quote and Start Your Project

BEPeterson is your go-to for expert fabrication services. Get robust metal parts for power generation that improve daily operations and allow you to work with confidence.

Full Service Metal Fabrication Since 1935

Since 1935 BEPeterson has set the standard for custom metal fabrication of heavy-gauge metal parts and equipment.