- ASME/PED/CRN

- ISO 9001:2015 NSAI Certified

Defense and Military Fabrication

BEPeterson, under contract to the Navy or to one of many tier-one naval suppliers, has supplied multiple projects of complete test systems, including pressure vessels, automation and controls and testing.

All work is completed in our Avon, Massachusetts facilities. BEPeterson holds the American Society of Mechanical Engineers (ASME) single certification mark and a certificate of authorization. Our team designs and manufactures military metal elements in conformity with the ASME Boiler and Pressure Vessel Code. BEPeterson designs/develops and manufactures under an NSAI-registered I.S. EN ISO 9001:2015 Quality Management System.

Cage Code# 3EB40 Unique ID# R886H1XM69T5 JCP# 0077653

Our Products

Our team effectively acquires and manages raw materials on a large scale, allowing us to be one of the leading providers of military metal fabrication and giving us the capability to take on major projects. We’re your single-source technology solution to design, engineer and fabricate robust military metal vessels.

Please review our Capability Statement.

BEPeterson Certifications for the Defense Industry

BEPeterson takes compliance seriously. We’ve worked hard to ensure we satisfy the industry codes, and all our defense metal fabrication solutions consider safety, risk and security.

JCP Certified Company

Our Joint Certification Program (JCP) certification allows us to receive crucial, unclassified technical military data to produce high-quality military metal fabrication that responds to the needs of the defense industry.

Certified Commercial and Government Entity (CAGE)

As a certified defense metal fabricator, we also hold a CAGE code, which enables us to participate in government procurement processes and contracts. You’re assured of reliable solutions for testing vessels, filter housing and all other defense applications.

Case Studies

Since we have ample experience working with the United States (U.S.) Navy and its contracting suppliers, our designers and engineers possess the skills to start and finish any military project.

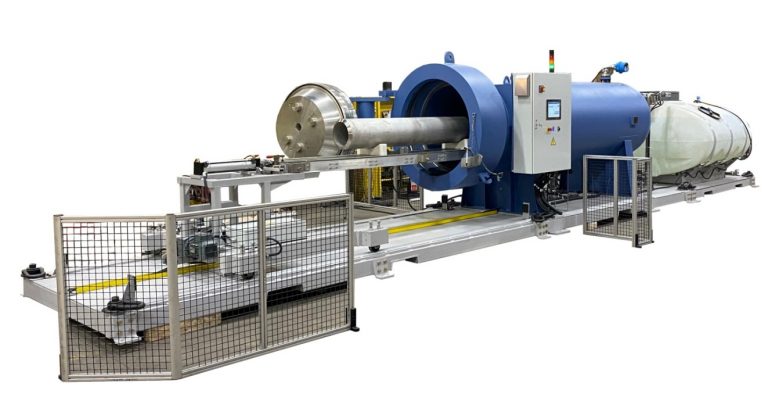

SAIC

BEPeterson supplied a custom turnkey hydrostatic testing system to SAIC, a prime contractor to the United States Navy. The BEP engineering team worked extensively with SAIC and subcontractors technical staffs from initial concept and all the way through on-site installation and commissioning.

The test chamber skid with the loading/unloading skid is roughly 6 feet W by 30 feet OAL, while the attached water supply skid is approximately 8 feet by 8 feet.

Test vessel Operating Pressure: 2500 PSIG at 100 degrees Fahrenheit MAWP: 3000 PSIG MDMT: 32 degrees Fahrenheit

The test chamber shall has an extendable rail system with provisions to load and secure the units under test. The system was fully integrated with operator-friendly controls and all electrical and electro-pneumatic controls were mounted in an IP64/NEMA 4 enclosure and met the requirements of NFPA 70 (NEC)

BEPeterson’s facility performed a factory acceptance test (FAT) prior to acceptance and shipment. BEPeterson was responsible for field installation and training at the job site.

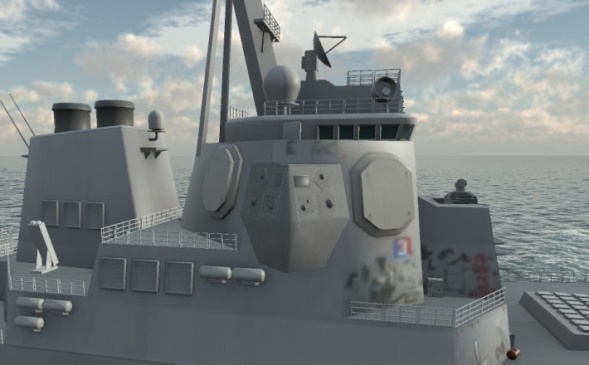

Northrop Grumman

Glycol reservoir vessels for the ongoing U.S. Navy SEWIP – Surface Electronic Warfare Improvement Program (see attachment). Multiple pressure vessels are produced annually to support the fleet deployment of this program. The pressure vessels are a necessary component in constructing the SEWIP Block 3 System.

Teledyne

BEPeterson has produced several test vessel systems for Teledyne. These systems are utilized to test submarine electronic cables for the Navy. The pressure vessels have been fitted with QAC—quick opening closures, which improve efficiency and operator safety.

General Dynamics

Currently on order from General Dynamics is a 28-inch O.D. by 216-inch S/L CS pressure chamber designed to 1000 PSI @ 100 Degrees F. The test vessel will have a quick-opening tool-less hinged closure for ease of access and safety. The system is also being designed to accommodate a conveyor system.

Navel Supply Systems Command (NAVSUP)

BEPeterson is under contract to manufacture 30 replacement air flask vessels from the Naval Supply Systems Command (NAVSUP). The air flasks will be installed on Henry J. Kaiser class replenishment oilers currently serving the United States Atlantic Fleet. This class of ships is operated by Military Sealift Command (MSC) and provides underway replenishment of supplies, provisions and fuel for US Navy ships and aircraft aboard aircraft carriers at sea. These ships have the capability of refueling and replenishing from either side of the ship and can replenish two ships simultaneously if needed.

HighCom Armor

BEPeterson partnered with HighCom Armor to engineer, design, and fabricate an ASME Section VIII Div. 2 pressure vessel and piping for the XTClave™ high-pressure system. From late 2023 through commissioning in July 2025, we maintained strict specifications, clear communication, and on-time, on-budget delivery. The system’s quick-access closure and cart loading enhance safety and efficiency while enabling lightweight, durable ballistic armor with complex geometries. Read the full case study here.

Syqwest & Progeny

BEPeterson has produced several test vessels for both of these companies. They both supply sonic devices to the Navy. The vessels have all been designed to 3000 psi.

Our Process

BEPeterson understands that the design and engineering phase is crucial for accurate outcomes. We’ve streamlined the entire process by working with you to devise a suitable solution that meets your specific defense requirements. This minimizes delays and downtime, keeps operations going and maintains high-quality levels.

1. The Design Phase

We support you during the design stage with custom solutions. Our process is efficient, ensuring compliance and functionality for practical results. We assist you with the following during the design phase:

- Support: Our team will verify the existing design or create a new one with you.

- Comprehensive approach: We build our systems to satisfy utility, safety and cost-effectiveness.

- Compliance: All our vessels are designed according to code as we are a holder of the ASME single certification mark and a certificate of authorization.

- Wide selection: Choose from our broad portfolio of military metal fabrication.

2. The Engineering Stage

During the engineering stage, we’ll start bringing your design to life using advanced technology. During this stage, you can look forward to:

- Advanced software: We use Codeware Compress, AutoCAD, Solidworks and Solidworks Simulation (FEA) design and engineering software.

- A dedicated engineer: Every project is assigned a specific engineer.

- Quality control: Our team reviews all products for manufacturability and compliance before material procurement and manufacturing commences.

Request Your Quote from BEPeterson Today

For custom military fabrication services that will elevate your next assignment, request your quote from us today or email us at sales@bepeterson.com.