- ASME/PED/CRN

- ISO 9001:2015 NSAI Certified

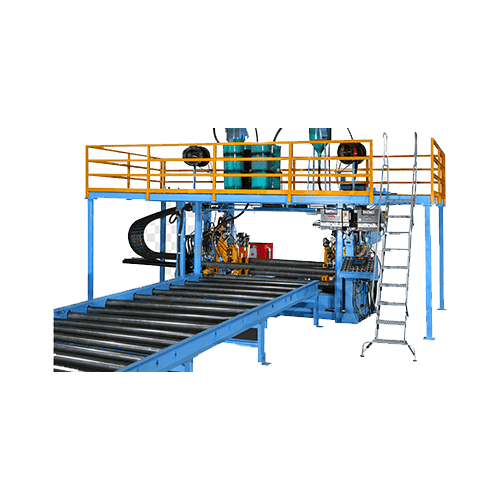

INDUSTRIAL METAL FABRICATION

In the broad category of “Industrial Products,” there’s only one name you need to know for large-scale custom metal fabrication—BEPeterson. With BEP’s capabilities in heavy-gauge custom fabrication — and your design — your custom product or component can be built just as you imagined — all with the quality and attention to detail your investment in custom industrial fabrication demands.

For decades, we at BEPeterson have provided high-quality, tailored industrial metal fabrication for several applications and industries. BEPeterson is your complete technical package and provides world-class service with unmatched attention to detail.

Our Products

- Architectural components

- Burners

- Complex assemblies, sub-assemblies and systems

- Ductwork, large, heavy gauge

- Filter housings

- Filter vessels

- Heavy custom fabrications

- Industrial fan and pump housings

- Stainless steel fabrications

- Tanks: Pressure

- Tanks: ASME

- Pressure vessel fabrication

- Utility boiler equipment

- Vacuum chambers

- Vacuum furnaces

- Vessels: ASME Code

Our Industrial Fabrication Process

At BEPeterson, we ensure quality and compliance with every project. Our professional team provides extensive support through the design and engineering phases for a successful, streamlined manufacturing process. Whether you need durable testing vessels or filter housings, we offer an OEM metal fabrication service to the highest standards.

1. Designing

We at BEPeterson take pride in providing you with the necessary design support. Once you reach out to us, we will assist you with:

- Support: Our team will work with you to verify the existing design or create a new one, working with you to design the most suitable option.

- Comprehensive solutions: Our systems are built according to function, safety and cost-competitiveness.

- Compliance: Being a holder of the American Society of Mechanical Engineers (ASME) single certification mark, we design all our metal vessels to be compliant and according to the ASME Boiler and Pressure Vessel Code.

- Wide selections: We design and develop a comprehensive list of custom industrial equipment, including skid assemblies, vacuum chambers, power and utility components, pressure vessels and more.

2. Engineering

Once we’ve concluded the design process, we move on to the engineering phase. During this stage, you can look forward to:

- A dedicated engineer: Every project receives a specific engineer to ensure your industrial metal vessels meet your and your industry’s requirements.

- The latest software: We use the latest software versions for designing and engineering your vessels, including AutoCAD, Solidworks Simulation (FEA), Solidworks and Codeware Compress.

- Review process: All products are reviewed for manufacturability and compliance before manufacturing and material procurement commence.

Get Your Industrial Project Started With BEPeterson

For unrivaled OEM metal fabrication services that can give you an edge, you need trusted industrial metal fabricators.

Get started today by requesting your quote or emailing us at sales@bepeterson.com for a customized product that suits your needs.

Full Service Metal Fabrication Since 1935

Since 1935 BEPeterson has set the standard for custom metal fabrication of heavy-gauge metal parts and equipment.