- ASME/PED/CRN

- ISO 9001:2015 NSAI Certified

SEWIP PROGRAM

BEPeterson – Trusted Manufacturer of Northrop Grumman Reservoir Vessels

Naval warships encounter a wide spectrum of threats including hypersonic missiles, ballistic and cruise missiles, rail guns, lasers, UAVs and torpedoes. One of the main threats is anti-ship missiles that use active radar homing for guiding purposes. Well advanced self-defense capabilities are essential for the navy to be able to sustain their operations and complete their missions.

As electronic warfare continues to evolve, Northrop Grumman is playing a key role in advancing defense technology for the U.S. Navy. One of the world’s leaders in state of the art aircraft & next-generation spacecraft, SEWIP is the next innovation in the latest line of advancements. The Surface Electronic Warfare Improvement Program (SEWIP) protects surface ships from anti-ship missiles, providing early detection, signal analysis and threat warning.

SEWIP Block 3 (the third block upgrade) is being developed by Northrop Grumman and adds Electronic Attack to the system. This emerging capability will meet the operational needs of the Navy by providing a scalable electronic warfare enterprise suite with improved electronic attack capabilities. Furthermore, the system will provide the Navy with the opportunity for future cost-savings and reduced size, weight & power. Please visit news.northropgrumman.com for additional information.

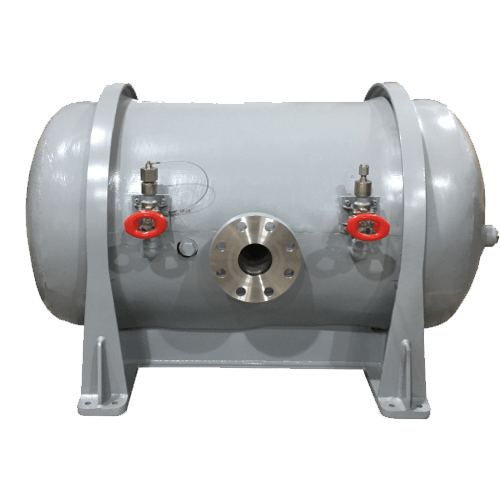

Reservoir pressure vessels are necessary components in the construction of the SEWIP Block 3 System.

BEPeterson has formed a productive business relationship with Northrop Grumman over the years through the manufacturing of high quality ASME certified pressure vessels. BEPeterson is the approved fabricator manufacturing the reservoir vessels found in the SEWIP Block 3 system (pictured). These vessels are manufactured with high quality stainless steel necessary to withstand pressures suitable for naval applications. Moreover, all of BEPeterson’s custom pressure vessels are manufactured and inspected following strict quality ITP protocols. BEPeterson is an approved ASME code pressure vessel fabricator. BEPeterson is ISO 9001:2015 Certified.

BEPeterson is a trusted custom pressure vessel fabricator due to extensive engineering design experience, accurate manufacturing, and meticulous quality inspection procedures. Our staff comprises qualified and experienced engineers, welders, and inspectors. We can cater to any custom industrial equipment requirement of customers. If you would like more details about custom pressure vessel fabrication service, please feel free to contact us.