- ASME/PED/CRN

- ISO 9001:2015 NSAI Certified

Defense

BEPeterson under contract to the Navy or to one of many tier one naval suppliers have supplied multiple projects of complete test systems including pressure vessels, automation, and controls and testing.

All work is completed in our Avon, Massachusetts facilities. BEPeterson is an approved ASME code pressure fabricator and is ISO 9001:2015 certified.

Cage Code# 3EB40 Unique ID# R886H1XM69T5 JCP# 0077653

SAIC

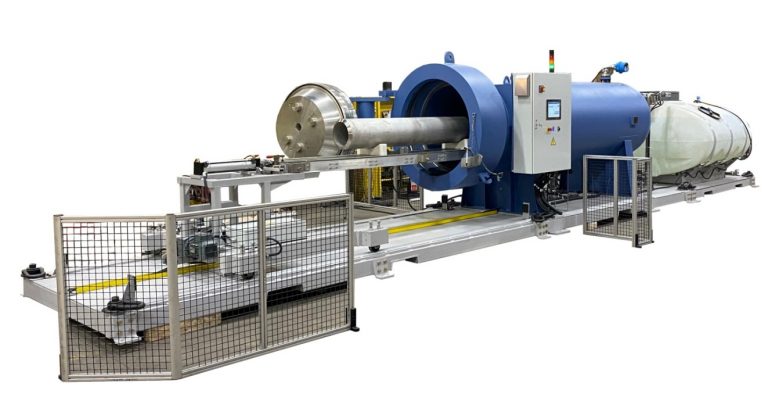

BEPeterson supplied a custom turnkey hydrostatic testing system to SAIC who is a prime contractor to the United States Navy. BEP engineering team worked extensively with SAIC and subcontractors technical staffs from initial concept and all the way through on-site installation and commissioning.

The test chamber skid with the loading / unloading skid is roughly 6’ W x 30’ OAL while the attached water supply skid is roughly 8’ x 8’.

Test vessel Operating Pressure: 2500 PSIG at 100°F MAWP: 3000 PSIG MDMT: 32°F

The test chamber shall has an extendable rail system with provisions to load and secure the units under test. The system was fully integrated with operator friendly controls and all electrical and electro-pneumatic controls were mounted in an IP64/NEMA 4 enclosure and met the requirements of NFPA 70 (NEC)

A Factory Acceptance Test (FAT) was performed at BEPeterson’s facility prior to acceptance and shipment. BEPeterson was responsible for field installation and training at the jobsite.

Northrop Grumman

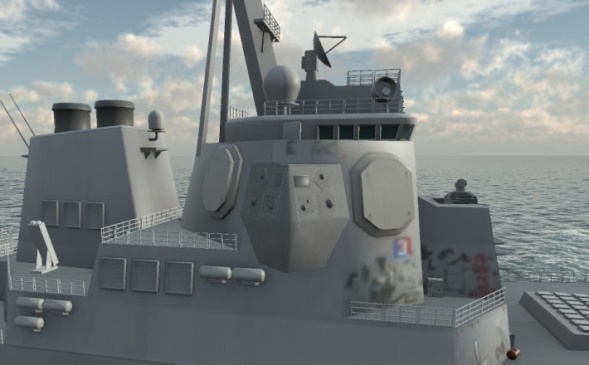

Glycol reservoir vessels for the ongoing U.S Navy SEWIP – Surface Electronic Warfare Improvement Program (see attachment). Multiple pressure vessels are annually being produced to support fleet deployment of this program. The pressure vessels are a necessary component in the construction of the SEWIP Block 3 System.

Teledyne

BEPeterson has produced several test vessel systems for Teledyne. These systems are utilized to test submarine electronic cables for the Navy. The pressure vessels have been fitted with QAC – quick opening closures which improve efficency and operator saftey.

General Dynamics

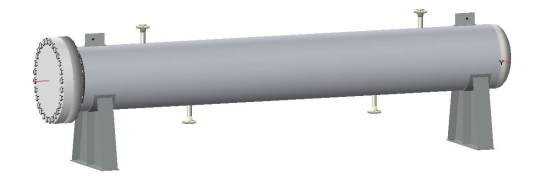

Currently on order from General Dynamics is a 28″ OD x

216″ S/L CS pressure chamber designed to 1000 PSI @ 100 Deg F. The test vessel will have a quick opening

tool less hinged closure for ease of access and safety. The system is also being designed to accomidate

a conveyor system.

Syqwest & Progeny

BEPeterson has produced several test vessels to both of these companies. They both supply sonic devices to the Navy. The vessels have all been designed to 3000 psi.