- ASME/PED/CRN

- ISO 9001:2015 NSAI Certified

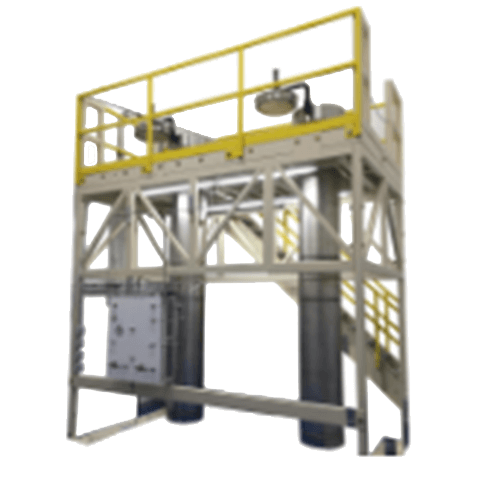

EXTRACTION VESSELS

BEPeterson custom designs and fabricates ASME code-stamped high-pressure extraction vessels for large-volume processing. Sizes furnished to date range from 50L to 300L. Operating pressures for CO2 range from 3,000 psi to 5,400 psi. We provide vessel design, FE analysis and a unique experience with various materials and manufacturing processes. Our quality is unsurpassed, and we are ISO-2015 approved. Each vessel is rigorously inspected and certified by a third-party ASME inspection service.

BEPeterson also has extensive experience with quick opening closures, which offer improved processing cycle times.

Let us help your company design and purchase the extraction vessel best suited for your requirements. We can fabricate Extraction Vessels and ship them to Canada with CRN registration and European PED Certification.

Custom Extraction Vessels From BEPeterson

BEPeterson can custom-make various extraction tank solutions to fit your industry and plant requirements. Our team works with you to devise the best system for your operations, ensuring you have a reliable extraction vessel with high-performance capabilities. Our highly skilled technicians and engineers pool their knowledge to meet and exceed industry standards. Get a tailor-made system that can boost efficiency and productivity.

1. Our Extraction Vessel Designing Phase

We work alongside you throughout the process to ensure we’re designing an extraction vessel according to your requirements. By focusing on safety, efficacy and quality, BEPeterson designs a solution that is fit for engineering and manufacturing. We provide the following support during the design process:

- Design support: We verify an existing design or create a new one with you so you have an extraction tank that responds to your industry and unique operations.

- Compliance codes: BEPeterson is a holder of the American Society of Mechanical Engineering (ASME) single certification mark and a certificate of authority. We manufacture all our extraction vessels according to the ASME Boiler and Pressure Vessel Code.

- Practical solutions: We focus on productivity and efficiency and design our systems with functionality, safety and compliance in mind.

- Broad selection: You have access to extensive options as we can custom design your extraction tank, ensuring we’ll have the solution you need.

2. Our Engineering Stage for Extraction Vessels

We start with the engineering phase once you’re satisfied with your design. Using cutting-edge technology and strict processes, we engineer a solution that’s ready for fabrication. During the engineering stage, you can expect:

- A dedicated engineer: We assign a dedicated engineer to each new project to ensure stringent quality control and superior outcomes.

- The latest software: Our team uses the latest software technology, including Codeware Compress, AutoCAD, Solidworks Simulation (FEA) and Solidworks, to design and engineer your extraction vessel.

- Thorough review process: Before we procure materials and start manufacturing, we review the design for manufacturability and compliance specifications.

2. Our Engineering Stage

We start with the engineering phase once you’re satisfied with your design. Using cutting-edge technology and strict processes, we engineer a solution that’s ready for fabrication. During the engineering stage, you can expect:

- A dedicated engineer: We assign a dedicated engineer to each new project to ensure stringent quality control and superior outcomes.

- The latest software: Our team uses the latest software technology, including Codeware Compress, AutoCAD, Solidworks Simulation (FEA) and Solidworks, to design and engineer your extraction vessel.

- Thorough review process: Before we procure materials and start manufacturing, we review the design for manufacturability and compliance specifications.

Extraction Vessel Industries and Applications

We build our solutions for high-pressure extraction in industrial applications. Our extraction vessels effectively extract various materials that are used further in the production line, keeping operations going. BEPeterson extraction vessels are used in the following industries:

- Oil and gas

- Manufacturing

- Mining and metallurgy

- Pharmaceutical

- Chemical

- Cosmetics

- Environmental applications

- Food and beverage

Get Your Quote From BEPeterson Today

BEPeterson can design and fabricate custom extraction vessels that give you a competitive edge. Get a robust, reliable extraction vessel with long-lasting performance that you can depend on. Request your quote today or email us at sales@bepeterson.com if you’d like more information.

International Standard Compliance

Cutting-edge Welding Processes

Rigorous Testing & Inspection

Detailed Reports

International Standard Compliance

- All vessels meet all applicable codes and standards (ASME, PED, and CRN).

- As a trusted ammonia tank manufacturer, BEPeterson delivers products with on time delivery, and to certified ISO 9001 quality standards.

Cutting-edge Welding Processes

- BEPeterson uses modern welding equipment, including submerged arc, which provides efficient and smooth welding of ammonia tanks.

- We meet the most sophisticated weld procedures using TIG, MIG, SAW, SMAW, FCAW with a variety of wire and fluxes.

- Qualified ASME Welders and an extensive radiographic capability support all types of ASME Section VIII code construction.

- Our welding capability is supported by a weld-engineering group consisting of multiple CWIs, and in-process weld inspectors.

Rigorous Testing & Inspection

- Every shell and tube heat exchanger is fully documented and inspected by authorized ASME Inspectors.

Detailed Reports

- BEPeterson provides full documentation, material test certificates, RT, and hydro test reports prior to shipment.

Full Service Metal Fabrication Since 1935

Since 1935 BEPeterson has set the standard for custom metal fabrication of heavy-gauge metal parts and equipment.