- ASME/PED/CRN

- ISO 9001:2015 NSAI Certified

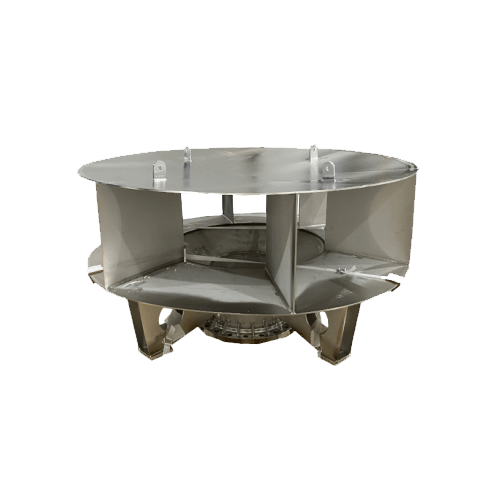

INVISIHEAD SYSTEM

BEPeterson – Proud Supplier of the Invisihead System

The Invisihead seawater intake & outfall system is environmentally responsible & self-reliant as no O&M (operation & maintenance) work is required. The system protects marine life – it is unattractive aquatic organisms, seaweed & debris. No ecological adverse effects are associated with Invisihead.

Unlike traditional O&M-intensive screening systems, the Invisihead system does not require yearly maintenance reducing costs in the longterm & netting millions in savings. On top of being eco-friendly, the investment pays for itself in a a few years. Please download the attached PDF & visit amecosys.com/elmosa to learn more.

BEPeterson continues to be a proud supplier of the intake head main assembly to American Eco Systems. We are specialists when it comes to custom metal fabrication & design. Furthermore, we utilize advanced manufacturing techniques and low cost material procurement to supply consistent & repeatable high quality products to our customers.

‘Finding someone able to work on our “unique” system was proving to be a challenge. It was not until we discovered BEPeterson. Working with their experts on many projects since 2009 made it all possible. Thank you BEP for being a faithful partner’

Elmosa Seawater Intake and Outfall Systems,

AES, LLC

If you would like more details about our custom fabrication service, please feel free to contact us.