- ASME/PED/CRN

- ISO 9001:2015 NSAI Certified

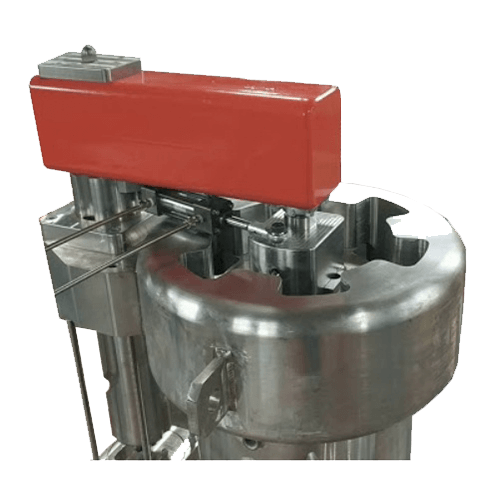

QUICK OPENING CLOSURES

Pressure vessels typically have bolted flanges, which require operators to spend considerable time removing and reassembling. Quick opening closures provide easy and fast access to pressure vessels, saving operators valuable time and effort.

In production or testing process environments where rapid access is necessary, a pressure vessel with a quick opening closure is the answer. BEPeterson specializes in the high-quality fabrication of engineering solutions, including quick opening closures for pressure vessels.

Types of Quick Opening Closures

Below are some of the different types of quick opening closures available for pressure vessels:

- Tool-less closures: These are high-pressure quick opening closures suitable for pressure vessels with vertical and horizontal configurations. As the name suggests, tool-less closures are designed for quick opening and closing without the use of other tools.

- Yoke-style closures: These are great alternatives to flanged closures that may be too big and time-consuming. These closures can be fitted with additional components such as sprocket drives, wrenches and chains for easier and faster operation.

- Threaded closures: Known for their simplicity and durability, threaded quick opening closures feature smaller fabricated components such as heads and hubs. They are among the most affordable options on the market and can meet demanding applications.

- Rotary self-lock closures: These are commonly used in the oil and gas industry because of their efficiency and reliability. They feature a rotating head mechanism that offers a secure and leak-proof seal for pressure vessels.

- Clamp ring closures: They feature a clamping mechanism for tight sealing, making them ideal for frequent opening and closing.

- Bolted closures: Bolted closures are also popular in the oil and gas industry but can be tailored to fit other industrial applications. Ideal for nominal pressure applications, they are versatile and easy to maintain and repair, making them common in various industries.

- Split closures: These allow swift access to equipment and pipelines with their split body design. They’re ideal for applications with limited access to other closure types due to space constraints.

Why Choose BEPeterson?

At BEPeterson, our services center on building lasting partnerships in the industry. We give our clients unparalleled service through:

- High-quality custom solutions: We build everything according to the customer’s requirements. We work closely with clients to understand their needs and use our technical expertise to devise a strategy unique to each project.

- Personalized service: To ensure we meet our customers’ needs, each project is assigned to a project engineer who oversees all its details.

- A wide range of expertise: Our broad range of expertise allows us to work on a diversity of industrial projects on top of fabrication.

- Low-cost procurement: With our wide network in the industry, we can procure premium materials at low costs. We pass these savings on to our clients, keeping prices reasonable without compromising quality.

BEPeterson Can Help With Quick Opening Closures

BEPeterson has experience applying quick-opening closures to a full range of vertical and horizontal pressure vessels. These closures are used extensively in the extraction and defense testing and development industries.

Talk with the BEPeterson engineers about a quick opening closure design for your pressure vessel system. Request a free quote online or email us at sales@bepeterson.com.

International Standard Compliance

Cutting-edge Welding Processes

Rigorous Testing & Inspection

Detailed Reports

International Standard Compliance

- All vessels meet all applicable codes and standards (ASME, PED, and CRN).

- As a trusted ammonia tank manufacturer, BEPeterson delivers products with on time delivery, and to certified ISO 9001 quality standards.

Cutting-edge Welding Processes

- BEPeterson uses modern welding equipment, including submerged arc, which provides efficient and smooth welding of ammonia tanks.

- We meet the most sophisticated weld procedures using TIG, MIG, SAW, SMAW, FCAW with a variety of wire and fluxes.

- Qualified ASME Welders and an extensive radiographic capability support all types of ASME Section VIII code construction.

- Our welding capability is supported by a weld-engineering group consisting of multiple CWIs, and in-process weld inspectors.

Rigorous Testing & Inspection

- Every shell and tube heat exchanger is fully documented and inspected by authorized ASME Inspectors.

Detailed Reports

- BEPeterson provides full documentation, material test certificates, RT, and hydro test reports prior to shipment.

Full Service Metal Fabrication Since 1935

Since 1935 BEPeterson has set the standard for custom metal fabrication of heavy-gauge metal parts and equipment.