A heat exchanger is a device used to exchange heat between two liquids, and a tube heat exchanger is one of its categories. It finds applications in industries which have high pressure requirements such as chemical companies, oil refineries, and more. A shell and tube heat exchanger is primarily a large vessel comprising a bunch of tubes or a tube bundle. There are two fluids, one which channels through the tube and the other through the shell over the tubes for heat exchange. The heat is transferred from tube to shell. BEPeterson has the experience and expertise of manufacturing these shell and tube heat exchangers for high pressure applications. This post discusses why BEPeterson is a good choice in case you need these heat exchangers.

More About Shell and Tube Heat Exchangers

Heat exchangers help in conserving energy by reducing fuel consumption and optimal use of materials. They help regulate temperatures of all types of fluids including high density, viscous fluids and semisolids such as oil, pulp, asphalt, and so on. They can handle harsh, abrasive chemicals, and hot oils as well and the materials for the exchanger need to be chosen accordingly. These heat exchangers are mounted on the outer side of fluid storage tanks. The tube materials are conductive which facilitates heat transfer between two fluids. The working of these exchangers is based on the suction principle. They help save energy as you need to pump into the exchanger only the required quantity of fluid is heated at a given temperature. This helps maintain the required temperature of the fluids when the product is in transit for shipment or needs to be loaded or unloaded. This saves the energy that would be required to heat an entire storage tank.

Benefits of Shell and Heat Tube Exchangers Offered by BEPeterson

BEPeterson complies with all the required industry norms and standards, and has an ISO 9001 certification. Here are some benefits of buying heat exchangers from the company:

-

- The company’s heat exchangers adhere to ASME, CRN, PED, and other applicable standards.

-

- They specialize in custom heat exchanger fabrication by understanding specific requirements of clients.

-

- The company uses standard manufacturing processes and advanced welding procedures such as MIG, SAW, FCAW, SMAW, TIG, and so on.

-

- The company has ASME certified welders who carry out detailed testing and inspection oa all the shell and tube exchangers. Aside from this they have CWIs, and in-process weld inspectors.

-

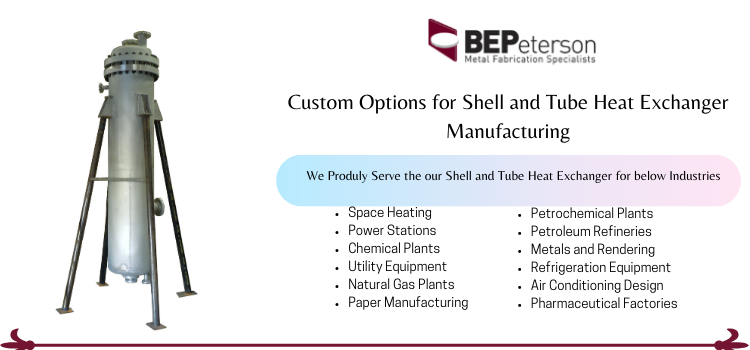

- They offer heat exchangers to diverse industries ranging from aerospace, oil & gas, and chemical to pharmaceutical, metallurgy, energy, petroleum, HVAC systems, and pulp and paper.

- These exchangers are quite compact and easy to maintain.

BEPeterson has been in the market for decades and is an expert at customizing these heat exchangers to suit your specific requirements. As a heat exchanger manufacturer, BEPeterson follows and complies with the set standards for manufacturing heat exchangers. The company has a team of experts to offer guidance related to technical aspects, inspections, and so on. In case of any requirement or questions you can reach them through phone or email.