Pressure Equipment Directive (PED) is a standard set by the European Union (EU) for the design and fabrication of pressure equipment. The standards that are set in the directive are very close to those defined by the American Society of Mechanical Engineers (ASME). This allows several international inspection agencies to verify and certify pressure equipment, and check whether they conform to the pressure equipment directives.

With this in mind, several pressure vessel manufacturers have started manufacturing the equipment in compliance to the PED. Learn how PED pressure vessels are manufactured with our step-by-step breakdown.

PED Manufacturing Methods

Several steps are involved in manufacturing pressure vessels that conform to the PED standards. The first stage is forming, which involves changing the shape of a part by applying a force. Forming can be carried out at three different temperature ranges, namely:

- Cold forming: This type of forming occurs at a fabrication temperature, which is extremely low compared to the material’s recrystallization temperature — the minimum temperature at which deformed grains are replaced by new undeformed grains.

- Warm forming: This is the middle range, where the fabrication temperature is above the room temperature, yet lower than the material’s recrystallization temperature.

- Hot forming: Hot forming is the process in which the fabrication temperature is very much above the material’s recrystallization temperature.

After forming, the next steps are:

- Pressing: Pressing gives the required part the desired shape with the help of a pressing machine.

- Spinning: After pressing, the spinning process gives the end of a pressure vessel or head the desired shape. The spinning machine has adjustable rollers, forming the material into the desired shape.

- Bending: Bending, also known as rolling, gives the material curves of the desired radius. This process uses a bending machine.

- Welding: This stage involves melting two or more materials to join them permanently. Different types of welding, such as gas metal arc welding and gas tungsten arc welding, offer unique advantages for different applications.

- Post-weld heat treatment (PWHT): This is one of the most important steps involved in the manufacturing of pressure vessels. In this step, thorough checks ensure the material strength of the part formed is retained. The residual stress introduced in the material by welding is reduced and redistributed by applying heat treatment. This helps improve the properties of the weldment.

- Assembly: This refers to joining the pressure vessel parts together.

- Painting: As the last step, paint is applied to the final product to protect it against corrosion.

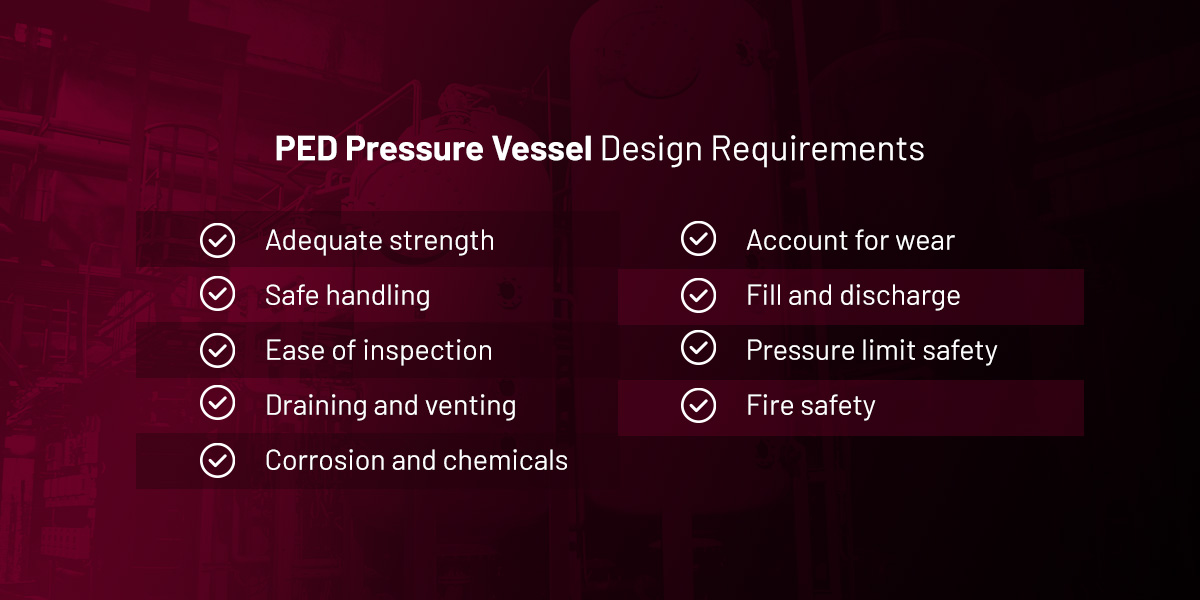

PED Pressure Vessel Design Requirements

The design requirements of PED-compliant pressure vessels vary by the type of equipment, its application and the associated hazards. Safety requirements also apply more generally across pressure vessels. Understanding these standards is vital because you must comply with the PED requirements to sell your pressure vessels in the EU.

Here are a few design requirements:

- Adequate strength: Pressure vessels must be able to handle the loads of their intended use. This includes considering factors like internal or external pressure, temperatures and corrosion.

- Safe handling: Consider how users can operate pressure vessels safely to minimize risk. Particular areas to focus on are closures and openings and using devices to limit access when the vessel is in use.

- Ease of inspection: Designs must incorporate ways to carry out safety checks on pressure vessels, including accessible openings for internal inspections.

- Draining and venting: Pressure vessels should have ways to drain and vent equipment to avoid water hammer and vacuum collapse and to allow safer regular cleaning, maintenance and inspection.

- Corrosion and chemicals: Pressure vessels should have adequate protection against corrosion and chemicals.

- Account for wear: Pressure vessels should resist wear from erosion and abrasion by incorporating additional material thickness or by allowing for easy replacement of high-wear parts.

- Fill and discharge: Users of pressure equipment should be able to safely fill and discharge vessels, such as ensuring safe connections and disconnections.

- Pressure limit safety: PED compliance requires pressure vessels to protect against the risk of pressures that exceed the limits of a particular vessel. This includes safety devices that monitor temperature and limit pressure, alarm systems and fail-safe modes.

- Fire safety: In the event of a fire, pressure vessels should be designed to mitigate damage.

Testing, Traceability and Labeling in PED Manufacturing

Tests and inspections ensure that the required design aspects are executed during PED vessel manufacturing.

This begins when forming component parts to confirm they are free of defects. Joints are also checked and can only be carried out by qualified individuals and to a specific operating procedure approved by a third party. Manufacturers should also perform nondestructive tests on joints.

From sourcing the materials to the final test, manufacturers must also ensure traceability of the materials that make up each of the component parts.

The final test visually examines every part of the pressure vessel, inside and out. As part of this process, a hydrostatic pressure test may be used as a proof test to check the vessel’s pressure containment. Checking any safety devices for full compliance also occurs at this final stage.

Pressure vessels must carry a CE marking. Compliance also requires other labeling regulations, such as the year of manufacture, a means of identifying the product, like a serial number, and the minimum and maximum pressure limits. These labels must be marked on the pressure equipment or with a data plate.

Find Fully Tailored Solutions for Your Pressure Equipment Needs at BEPeterson

The high quality standards of PED pressure vessels have many benefits, including longer service life and enhanced safety. However, shipping a pressure vessel from the United States to Europe requires detailed documentation that can be more stringent than ASME requirements.

By choosing an experienced certified metal fabricator, you can ensure you meet PED requirements without the headache of documentation. At BEPeterson, we can build your PED-certified pressure vessel and ship it to any European Union country while providing full documentation.

BEPeterson is ASME and ISO 9001:2015 certified and has delivered high-quality equipment to its customers since 1935. Request a free quote today.