Since 1935, BEPeterson has been supporting a variety of industries by providing an array of industrial products and services. Many industries have benefited by choosing our ASME tanks, pressure vessels, skid assemblies and , CRN pressure vessels, vacuum chambers , and stainless steel pressure vessels, to name only a few. One sector that has reaped significant benefits for over forty years is the Power and Utilities industry. Over this time, BEPeterson has provided many solutions in terms of products and services that have strengthened the position of our OEM customers in the industry.

Products and Services that Advance the Power and Utilities Industry

BEPeterson is renowned for its fabrication services and we have a long history of success when it comes to fabricating products for the Power and Utilities industry. We offer the following products to our power and utility OEM customers:

- Ash Control Valves

- Boiler components

- Low NOx Burners

- Burner Tips

- Ceramic / Refractory Lined Products

- U Certificate of Authorization

- Cyclones

- Dampers

- Low NOx Wind Boxes

- Sofa Registers

- Vortex Finders

We also provide a variety of services including Low NOx Burners, Co-gen duct work, assembly of coal compartments, and designing and manufacturing overfire air systems. We even offer custom hard-facing services for applications in which resistance to abrasion is crucial.

Excellent Capabilities for Creating World-Class Products and Services

At BEPeterson, we are able to offer the aforementioned solutions due to our world-class manufacturing capabilities. Our state-of-the-art, 78,000 square foot facility has the latest in design and manufacturing equipment. We have the capabilities to provide industrial products with the following specifications:

- 100″ Overall Length

- Full Vacuum Pressure up to 3,000 PSI

- Up to 13″ in Diameter

- Overall Vessel Weight up to 40,000 lbs.

Our metal plating equipment allows for the fabrication of industrial vessels with thickness specifications ranging from 14 gauge up to 1″. For large vessels, we provide crane lifting services, with capacities up to 25 tons and with a hook height of 25 feet. We also provide trusted subcontractors who will maintain the same level of product quality and efficiency should a specific need arise that cannot be met by BEPeterson’s in-house capabilities.

At BEPeterson, you can be assured that your product will be delivered to you on time, with proper documentation, and will be accepted for applications around the world.

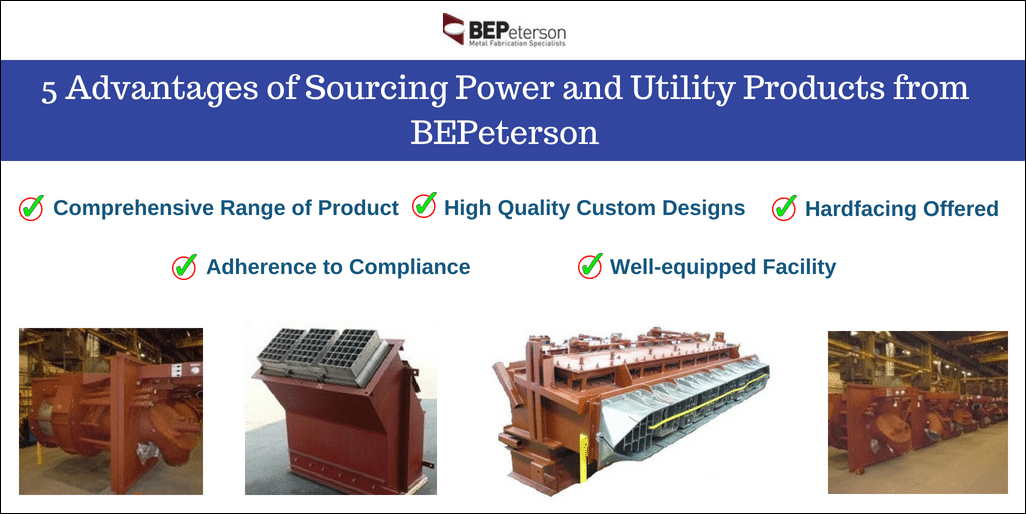

5 Advantages of Sourcing Power and Utility Products from BEPeterson

BEPeterson has established a strong footprint in the power and utility industry for over fifty years due to the following reasons:

1. A Comprehensive Range of Product Selection

We manufacture products, which are integral to the power and utility industry. Some important products include:

- Ash control valves

- Low NOx burners

- Burner Tips

- Boiler Components

- Gas Conversion Piping

- Coal Component Assemblies

- Overfire Air Systems

- Low Nox Wind Boxes

- Vortex Finders

- Cyclones

- Dampers

- Sofa Registers

2. High-Quality Custom Designs

All the above-mentioned products are available in standard sizes, as well as offered in custom designs. We use only high-quality materials for building the products. The following examples will help you understand the quality of materials used for constructing various products.

- Wall-fired burners are made from high-temperature stainless steel, as well as carbon steel.

- Nozzle tips for gas and coal wall-fired burners are created using high-temperature stainless steel material. Additionally, the overlay protection adds to their lasting performance.

- We use stainless steel materials with high-temperature capacity, as well as carbon steels for producing SOFA windboxes.

All the products can be either custom-designed to particular specifications or offered as a retrofit to meet the existing equipment. We understand that in a power and utility industry, a small error may be dangerous, or expensive. Thus, every product undergoes a strict inspection before leaving our premises. BEPeterson investment in inspection and testing provides highly accurate products, which work as expected.

3. Hardfacing Offered

There are several critical applications that demand high abrasion resistance. Our custom hard-facing services help clients meet this requirement easily. It means tough or hard materials are applied to the base metal to increase its wear resistance. This process is also used to restore a worn surface.

4. Adherence to Compliance

We are ISO 9001: 2015, as well as ASME, NSF, and TUV certified. Also, we are National Board Certified to ASME Section VIII. Our weld procedures are certified to ASME Section 9, SMAW, and GTAW, GMAW, FCAW, and SAW.

5. Well-Equipped Facility

BEPeterson has 88,000 sq. ft. manufacturing facility, with high ceiling bays. This makes us one of the largest manufacturers in the Northeast. We employ advanced manufacturing technologies for fabrication and design.

The above-mentioned reasons coupled with our industry-wide experiences have helped us establish in the domain marked by industry players.